OUR MACHINERY

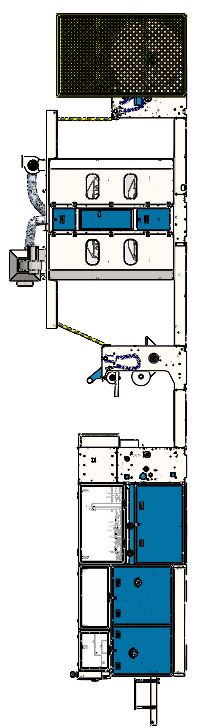

IRIS

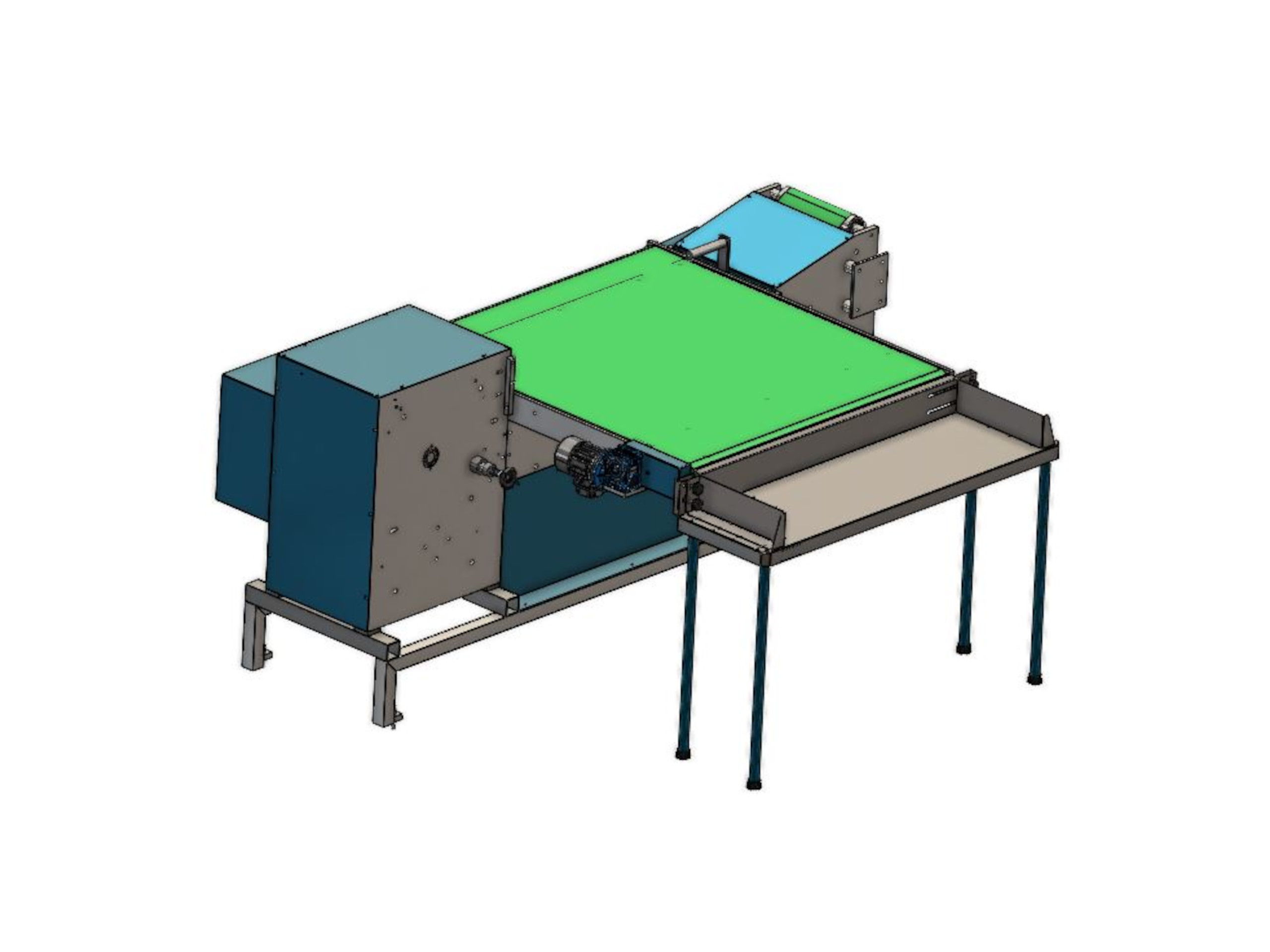

Flat & Satchel paper bag machine perfore type

IRIS

IRIS produces flat & satchel paper bags in various dimensions. Our focus is to provide you a machine that is easy and safe to operate & maintain.

Industry 4.0

We developed a Machine - Office two-way communication program where machine production information is transferred-displayed & processed.

Technical parameters

IRIS170

x 40mm - 170mm

y 140mm - 340mm › DOUBLE CUT

y 350mm - 550mm › SINGLE CUT

IRIS250

x 70mm - 250mm

y 190mm - 420mm › DOUBLE CUT

y 430mm - 620mm › SINGLE CUT

or

y 240mm - 420mm › DOUBLE CUT

y 430mm - 700mm › SINGLE CUT

IRIS350

x 80mm - 350mm

y 190mm - 420mm › DOUBLE CUT

y 430mm - 620mm › SINGLE CUT

or

y 240mm - 420mm › DOUBLE CUT

y 430mm - 700mm › SINGLE

Extra equipment

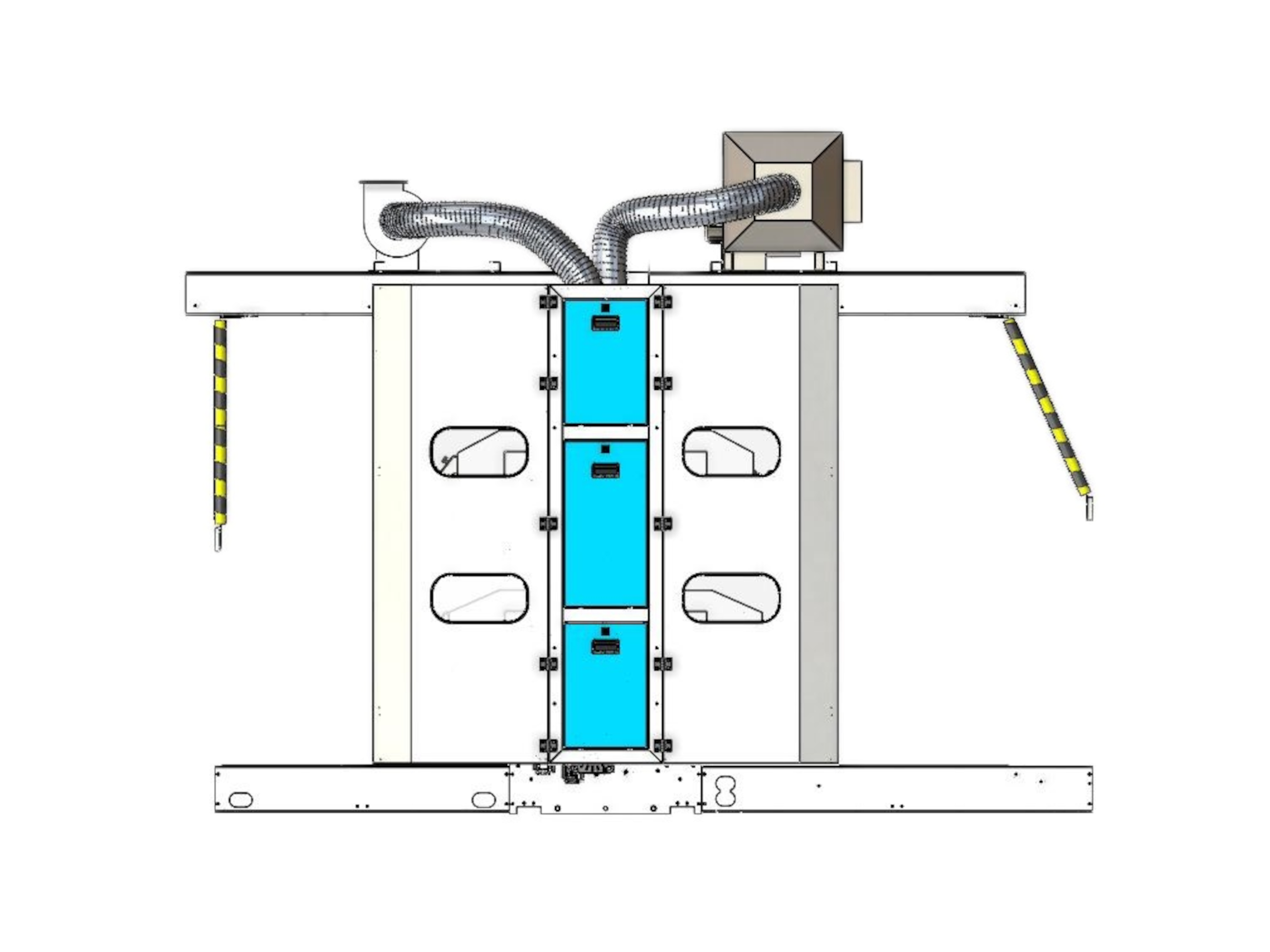

Window Station

System for the introduction of a transparent frame, along the paper bag, for the creation of a window.

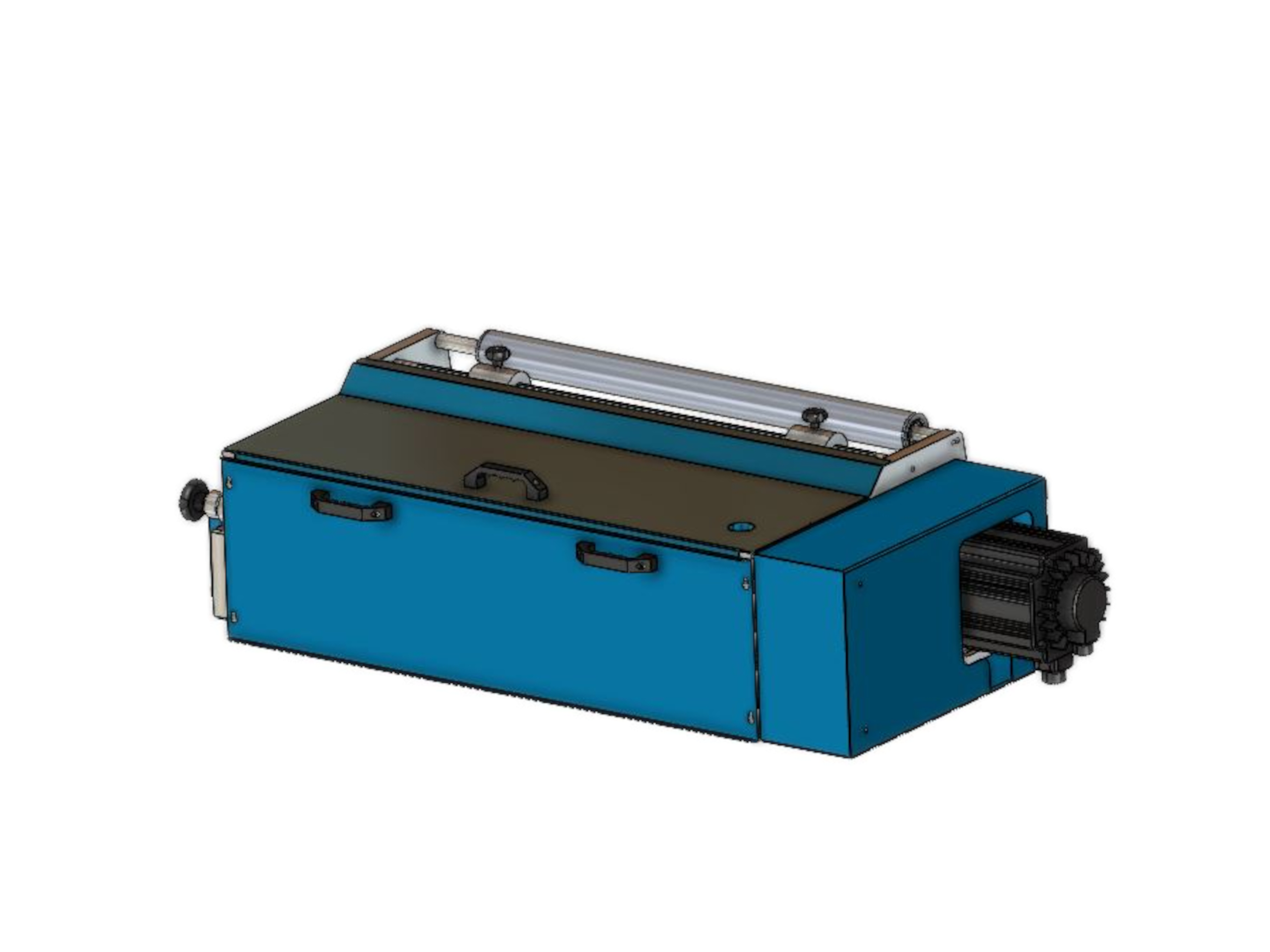

Flexo Printer

Inline flexographic printer

SDP

Equipment for the creation of a double bag from two different paper qualities.

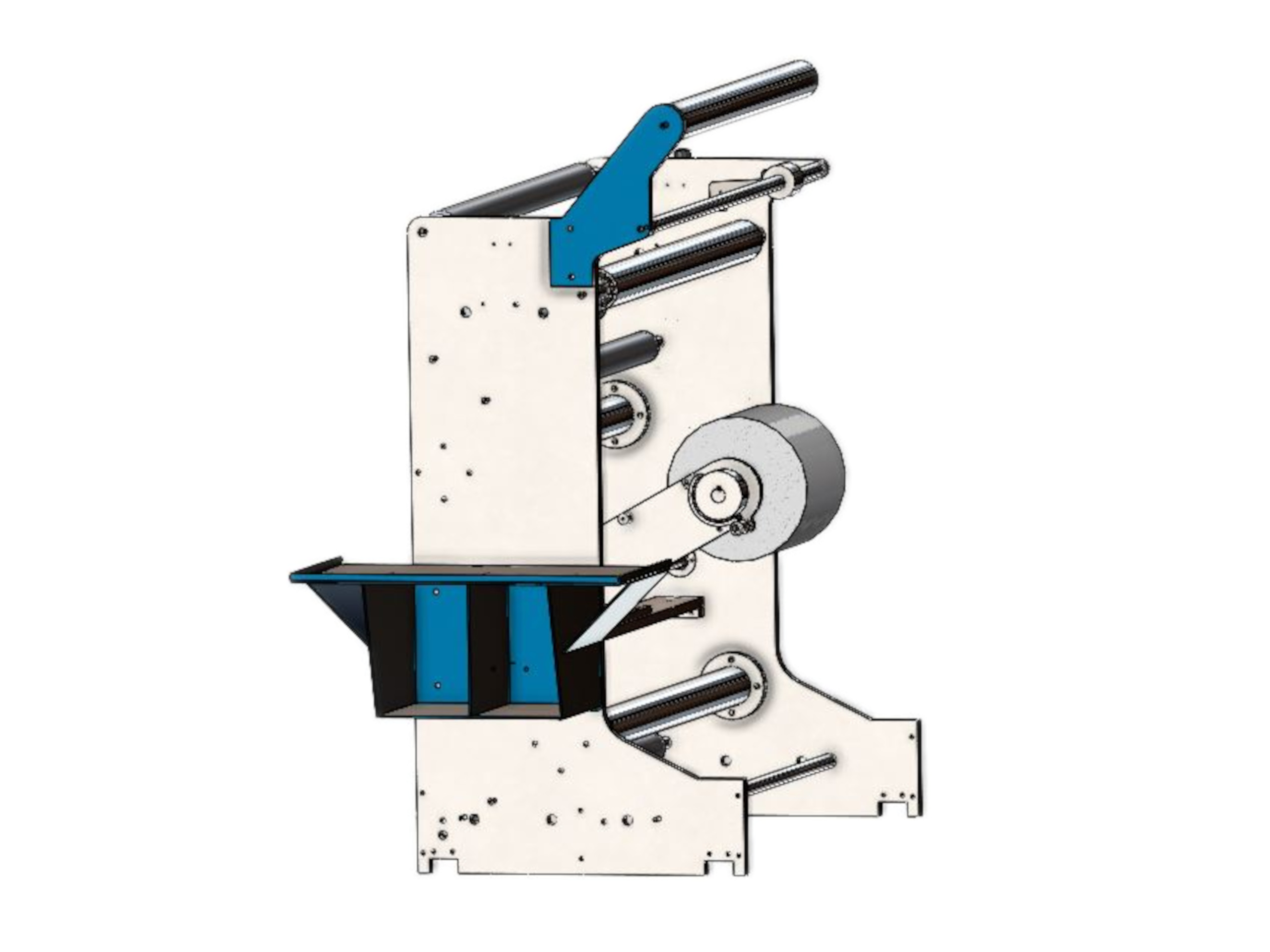

LPB

Equipment that allows the exit of the paper bag in horrizontal position in bundles.

Punching unit

System for the introduction of holes on the upper part of the bag.

Handle

System for the introduction of a handle in the form of a smile on the upper part of the bag.

Hot Melt System

Automatic adhesive device for setting hot glue along the paper, without spraying on the perforation.

Cold Glue System

Automatic adhesive device for spraying cold glue along the paper, with an analogue valve.